Get the weekly SPARTANAT newsletter.

Your bonus: the free E-Book from SPARTANAT.

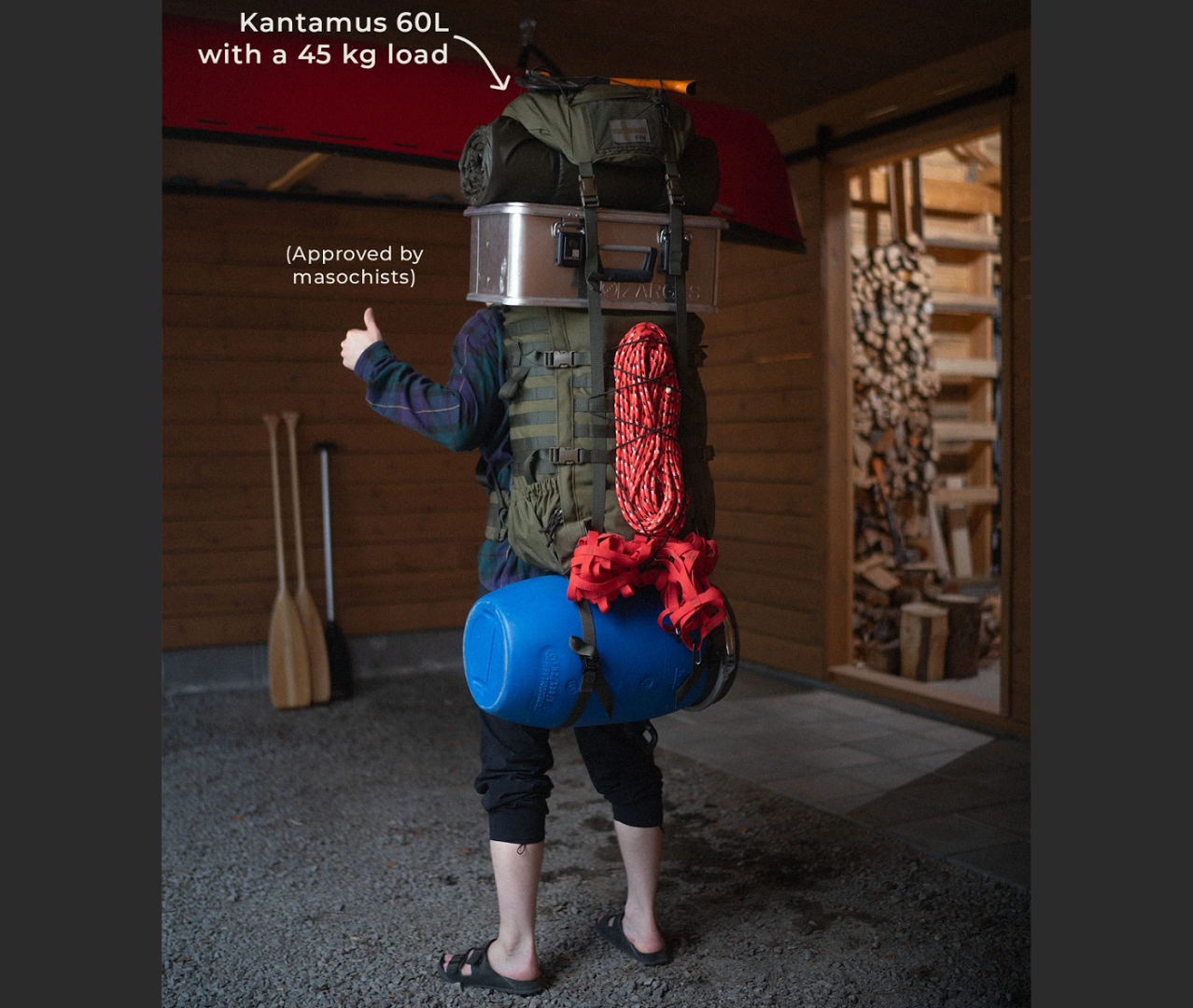

“The Finnish approach to equipment”

SAVOTTA, a Finnish brand, specializes in high-quality outdoor and military gear. In an interview, product manager Stefan Melander discusses the "Finnish way of gear," emphasizing reliability and user-friendly design. He highlights the importance of personal military experience in the design process and collaboration with the Finnish Defence Forces.

SAVOTTA from Finland makes outstanding gear. Backpacks, plate carriers, pouches and much, much more. You can find detailed reviews of some of their gear on our site. We had the chance to do an interview with Stefan Melander, product manager and head of our product development at SAVOTTA. He explains to us what “the Finnish approach to equipment” is.

SPARTANAT: SAVOTTA is actually very well known for excellent outdoor gear, but SAVOTTA MILITARY produces specialized military gear. What is for you the "Finnish way of gear"?

Stefan Melander: First of all we are just one brand, SAVOTTA. SAVOTTA Military (and SAVOTTA Outdoor) are just used in social media to serve our two main client bases. Maybe someday we will have separate brands for these two segments, but that’s a thing of the far future, if ever.

Regarding the “Finnish way of gear”, we have actually written a whole article on this subject, but it’s not released yet. But summarized: for us, it’s about making truly sensible equipment that does what it needs to do, in the sort of conditions we have around here.

For us this means an emphasis on how the FDF (Finnish Defence Forces) work, the equipment that’s used and the people who use it. A reservist military in wartime is made up from ordinary people, not “tactical gear enthusiasts” (of course there are some of them, but they are a minority), so the equipment needs to be easily understandable, easy to use and reliable. If you don’t understand how to use something, then you will probably use it wrong and not get the intended effect out of it.

There’s also a deeper personal level to this work. We don’t just do business, in the end we design and manufacture equipment for use in the worst possible situations by our allies, our own people, our friends, family and ourselves. As such we really can’t do a half-assed job just for the money.

SPARTANAT: Which gear from SAVOTTA is in use with the Finnish army?

Stefan Melander: Too many to count, really! Most of the gear we have made for the FDF in the past 60 years is still in use, and this includes an uncountable number of specialist items for all sorts of uses. There are also many cases which we can’t name publicly, due to the projects being classified or otherwise restricted.

But some of the bigger, easily recognizable equipment which is in active use would include:

- M85 combat load carrying system

- LJK paratrooper pack and the later Modular LJK

- M05 combat load carrying system, vest, backpacks, pouches

- M17 plate carrier, we designed the current iteration/update in 2022

- M23 belt and pouch kit, used with the M17 plate carrier

- M20 combat and Medic packs

- Tents, numerous different models

- Sleeping pads

- Carrying systems for various heavy weapon systems

Overall, it’s probably impossible to serve in the Finnish Defence Forces without being subjected to gear that we’ve made and/or designed. This has been the case since the 1960s.

SPARTANAT: When we pick up a SAVOTTA military pouch, the first thing we realize it’s robustness: all the world went lighter, Why 500D with a backer?

Stefan Melander: Not sure about the “Why 500D with a backer?” part, but I think I understand the overall intention here. Indeed, we don’t do ultralightweight gear, but of course we do our best to shave off weight where possible. Weight savings overall are a phenomenon that we are looking at more and more, but a big wheel turns slowly.

We have some historical burdens to shed here, for many years SAVOTTA simply used the same materials for everything we did, and that was very much dictated by what our big military contracts were like at the time. For a long time that was pretty much 1000D Cordura and that’s it! Nowadays, we of course still use 1000D, but many of our backpacks (for example) are made with partially 1000D, partially 500D, construction.

No matter what we do, we will for sure always put a lot of emphasis on the service life and reliability of our gear in extended use. But the reality is of course that extreme long service life needs extremely strong materials, which have the downside of being heavier.

But there is value to robustness too. When you can rest assured that your gear just will not wear out, stretch out, rip or what ever no matter what (almost…) you do, and no matter if you do it for a year, two or ten, that’s cool too! But you would of course also want to carry as little weight as possible.

SPARTANAT: Most of you are reservists. How important is your personal experience in the Army for designing military gear?

Stefan Melander: Very important. Having a solid understanding of soldiering life and how this sort of equipment is used makes designing it easier. When you have experienced problems with gear personally, you know not to make the same mistakes.

On top of just personal experience, we naturally work with a lot of current end-users and listen to their thoughts and feedback. Due to all the military work we do we have very close ties to the FDF (Finnish Defence Forces), and design work is always done in very tight co-operation to make sure we meet the needs and demands.

Besides tight-knit contacts with our local military and other governmental organizations and their end users we also keep our ears open for feedback from the front in Ukraine. Our current best-selling Kahakka backpacks were partially born from feedback we got from Ukraine after donating a bunch of gear (including our old Jääkäri S backpacks) there in early 2022.

But again, personal experience is a must to be able to discuss these things with end-users on a deeper level, and actually understand what’s being said. If you have no idea of the work they’re doing you can’t really get anything out of such discussions.

So yes, personal military experience = very important. But that alone doesn’t do it, you need to have a designer's mind to be able to turn feedback and ideas into actual gear.

SPARTANAT: Making military gear, how is the design process? How are you working as a designer?

Stefan Melander: It’s quite a process, and the work overall is very diverse.

When doing project work for various clients we are often constrained by very tight deadlines, which means that we have to really focus on the critical requirements, with “nice to have” things taking second place.

Sometimes we work from very detailed (also very constraining) lists of requirements, sometimes from less detailed ones, sometimes from almost nonexistent. Requirements may be hundreds of lines of technical material specs, detailed functionality descriptions etc. or they may simply be “make a good backpack to carry this set of equipment”.

In any case, these sorts of projects require good imagination and a thorough understanding of how stuff is made. You need to be able to understand the requirements in-depth and then be able to somehow visualize and imagine what this would look like in the form of an actual product. That imagined piece is then turned into sketches and drafts, which in turn are made into the first prototype. From there on its iteration upon iteration until the required end-result is achieved.

Many project jobs involve field-testing, going through the feedback etc. All in all, these projects are typically quite time-consuming, but good communication is a must when you want to achieve something that really meets the requirements of the actual end-users.

On the other hand, when doing our own products, the job is usually much more comfortable. After all, it is us ourselves who come up with the requirements for what we want to achieve, and we ourselves who determine the deadlines etc.

An overall challenge is the balance of project work and commercial stuff for our own selection. When some big project drops on our desks that usually means that we sacrifice something that we’ve been working on for ourselves, at least for a little while. But such is life in the defence business!

In the end, no matter if it’s a project job or our own products, we always do our best to come up with a sensible, functional design that does what it needs to without being overly complicated. Having our production in the EU and sourcing 97% of our materials from EU manufacturers (2% from the US, 1% from Asia) means that our costs are relatively high as is. We can’t mess around with needlessly complicated designs which would blow up the price. We leave such silly stuff to our competitors with manufacturing in China etc.

SPARTANAT: Stefan, kiitos (thank you) for the interview.

You can find all the great gear from SAVOTTA on their website.

SPARTANAT is the online magazine for Military News, Tactical Life, Gear & Reviews.

Send us your news: [email protected]

Ad

similar

Get the weekly SPARTANAT newsletter.

Your bonus: the free E-Book from SPARTANAT.