Get the weekly SPARTANAT newsletter.

Your bonus: the free E-Book from SPARTANAT.

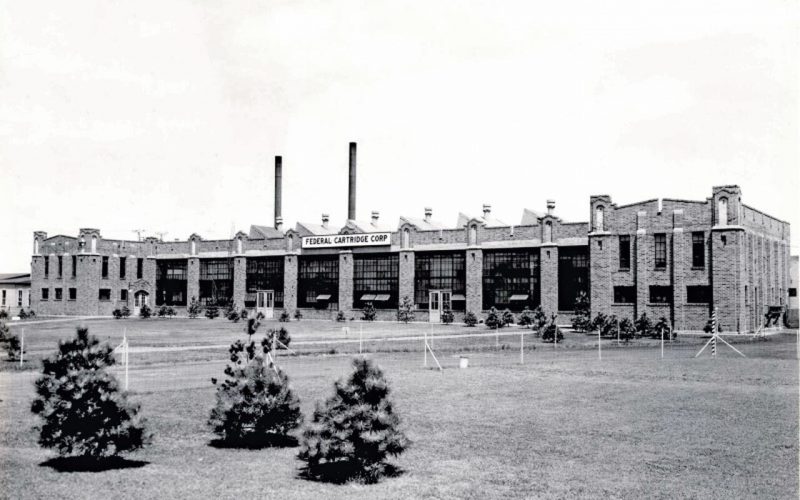

HISTORY: 100 years of Federal Ammunition

Federal, the world's largest ammunition manufacturer, upholds its promise of performance in every cartridge produced. From its humble beginnings in 1922 to its state-of-the-art facility today, Federal remains an industry leader in producing quality ammunition for sport, hunting, and law enforcement.

Each cartridge is a promise. Whether the bullet leaves the barrel during hunting, in a competition, or during a day with friends at the shooting range, it must perform. It must hit the target, show its effect - both literally and figuratively. Ammunition is the direct connection between the shooter and the target. Federal, the world's largest ammunition manufacturer, measures itself against this claim.

Humble beginnings

It all started modestly in 1922 when Charles L. Horndie took over a small ammunition manufacturer. Knowing he was up against tough competition from established ammunition manufacturers, he began a novel strategy. Horn worked to get his products, which at that time consisted only of shotgun shells and were produced in an 800 square meter factory, onto the shelves of barber shops, gas stations, and grocery stores. The strategy worked and helped the company grow. In 1941, Federal secured an $87 million contract from the US government to build and operate the "Twin City Ordnance Plant" in Arden Hills, Minnesota, which made a significant contribution to military ammunition and other defense products during World War II, the Korean War, and the Vietnam conflict.

Industry leader

The "Federal Ammunition Factory" in Anoka, Minnesota, is now a 65,000 square meter state-of-the-art facility where 1,400 employees work around the clock in three shifts to produce millions of centerfire, rimfire, and shotgun cartridges as well as various components daily. The factory is vertically integrated, meaning raw materials are delivered to one side and the finished product leaves the factory on the other side. Essential for quality control is the fact that production is self-sufficient - all the personnel needed to produce quality ammunition are on-site, including machine operators, plumbers, and electricians. There is a machine shop, equipment maintenance, manufacturing engineering, product development, marketing, and sales. To ensure the ammunition performs at this high level, the site maintains 16 test firing ranges. "We don't just buy parts and put them together or have other companies load cartridges for us," says Jason Vanderbrink, company president. "We do it all in-house, and every day our production facilities consume tons of plastic, lead, brass strips, copper, steel, etc. These materials are used to build our own bullets, shot, cases, primers, and more. The consumer benefits because we have complete quality control, and our employees have decades of experience."

Ready for the next century

All of this makes Federal the industry leader in sport, hunting, and law enforcement ammunition, a position the company aims to maintain and expand in the decades to come. "In the past 10 decades, one constant has always been the spirit of innovation that has accompanied the company since its inception," says Jason Vanderbrink. This has fostered the development of products that have changed shooting and made Federal a global leader in ammunition manufacturing. "It started a century ago with our founder, Charles Horn, and we are proud to continue this legacy today. Federal is better positioned than ever, and we look forward to serving shooters around the world for the next 100 years. We are just getting started!"

FEDERAL on the web

SPARTANAT is the online magazine for Military News, Tactical Life, Gear & Reviews.

Send us your news: [email protected]

Ad

similar

Get the weekly SPARTANAT newsletter.

Your bonus: the free E-Book from SPARTANAT.