Hol Dir den wöchentlichen SPARTANAT-Newsletter.

Dein Bonus: das gratis E-Book von SPARTANAT.

Dynamic Arms Research – Werksbesuch in Fraureuth

DAR schau her! Nicht weit von Zwickau entfernt sitzt ein kleines deutsches Unternehmen, das sich in den letzten Jahren einen Namen im Bereich AR15/AR10 Bau, Entwicklung und Herstellung gemacht hat. Wir finden es ist höchste Zeit, Dynamic Arms Research (DAR) einen Besuch abzustatten.

DAR schau her! Nicht weit von Zwickau entfernt sitzt ein kleines deutsches Unternehmen, das sich in den letzten Jahren einen Namen im Bereich AR15/AR10 Bau, Entwicklung und Herstellung gemacht hat. Wir finden es ist höchste Zeit, Dynamic Arms Research (DAR) einen Besuch abzustatten. Bevor wir uns aber die Waffen von Dynamic Arms Research angesehen haben, wurde der CEO, Marcel Schreiterer, von uns interviewt.

SPARTANAT: Hallo Herr Schreiterer, vielen Dank dass Sie uns heute und hier empfangen.

Schreiterer: Hallo, liebe Leser von SPARTANAT, ich freue mich Euch heute unser Unternehmen näher vorstellen zu können.

SPARTANAT: Erzählen Sie uns doch bitte zum Einstieg kurz etwas über ihre Person und die Entstehung von DAR.

Schreiterer: Angefangen habe ich eigentlich 2008 mit meiner Selbstständigkeit. Ich habe mich am bestehenden Markt orientiert und mir angesehen, was andere gut und schlecht machen. Erste Teile wurden noch während des Studiums entwickelt. 2010 wurde dann die Dynamic Arms Research GmbH gegründet. Zu diesem Zeitpunkt kamen noch viele Teile aus Lohnfertigung außer Haus.

SPARTANAT: Produktionsstandort der Teile im Ausland?

Schreiterer: Nein, wir haben hohen Wert darauf gelegt, die Produktion in Deutschland zu belassen. Die Teile kamen von einem Unternehmen in Tuttlingen am Bodensee.

SPARTANAT: Aber dort produzieren Sie nicht mehr aktuell?

Schreiterer: Nein, die Produktion kommt nun aus eigener Hand. 2015 haben wir das neue Firmengebäude, in dem wir gerade sitzen, bezogen und größtenteils in Eigenregie renoviert. Der Vorteil bei der Eigenfertigung erhöht den qualitativen Standard und gewährleistet schnellere Lieferzeiten.

SPARTANAT: Es kommt aber nicht alles aus Ihrem Werk?

Schreiterer: Natürlich nicht. Warum sollten wir zum Beispiel Magazine, Hinterschaft und Griffe herstellen, wenn der Kunde dann doch etwas anderes montiert. Wir haben uns bei allen Kunststoffteilen für Magpul entschieden. Bei den Abzugsgruppen verwenden wir einen Standard MILSPEC Abzug, den wir leicht überarbeiten. Auch Abzüge von Timney oder UHL verbauen wir häufig. SPARTANAT: Wenn man jetzt aber lieber einen Geissele Abzug nutzen möchte?

SPARTANAT: Wenn man jetzt aber lieber einen Geissele Abzug nutzen möchte?

Schreiterer: In Sachen Anbauteile anderer Hersteller sind wir recht flexibel, der Kunde kann selbst Teile mitbringen oder wir übernehmen die Beschaffung – einzige Voraussetzung: das Teil muss passen.

SPARTANAT: Die Läufe kommen von Lothar Walther nehmen wir an?

Schreiterer: So ist es, allerdings verwenden wir keine einbaufertigen Läufe, sondern lassen uns Rohlinge liefern. Wir passen dann das Patronenlager sowie die Barrel Extension an den Verschlusskopf mit minimalster Toleranz an. Üblicherweise hat der erste Schuss einen anderen Impuls bei der Zuführung ins Patronenlager bei den Standardverfahren. Durch unsere Verschlussanpassung existiert dieser Impuls nicht und jeder Schuss zeigt exakt das gleiche Verhalten. Weiterhin bieten wir handgeläppte Läufe (Anm.: feinste Art der Polierung) und auch Oberflächenveredelung der Läufe an. Dabei setzen wir auf Tenifer QPQ Nitrierung im Gegensatz zu anderen Mitbewerbern, die nur beschichten. Die Teniferierung ist eher eine Härtung als eine Beschichtung, das bedeutet, durch das Nitrieren geht die Behandlung 100 Prozent in das Material. Dadurch werden die Züge und Felder beeinflusst: Das Metall wird geglättet und das Verhalten verbessert.

SPARTANAT: Wie sieht es mit dem Drall der Läufe aus?

Schreiterer: Den kann man frei von 7 bis 14 wählen und wird an die Lauflänge angepasst.

SPARTANAT: Zum Lauf gehört konsequenter Weise ein Vorderschaft. Hier setzen Sie ja auch auf ein eigenes Konzept. Warum kein Quad Rail, KeyMod oder M-LOK?

Schreiterer: Unser System ist stabiler als KeyMod oder M-LOK. Natürlich können diese Systeme auch gewählt werden, aber wir favorisieren das unsere.

SPARTANAT: Glaubensfrage: Piston oder Direct Impingement?

Schreiterer: Wir bieten nur Direct Impingement (DI) an. Wir fragen unsere Kunden immer: „Wollt ihr mit dem Gewehr tauchen oder über 1.000 Schuss pro Woche machen?“ Das sind nämlich die einzigen Vorteile bei dem Pistonsystem. Oftmals wird ja behauptet, Piston sei besser in Sachen Verschmutzung – das ist aber falsch. Beim Pistonsystem verschiebt sich die Verschmutzung vom Verschluss zum Gaspiston Zylinder. Außerdem wirkt ein Kippmoment, welches die Präzision negativ beeinflusst.

SPARTANAT: Eure Waffen sind ziemlich teuer auf den ersten Blick, wie kommt das?

Schreiterer: Unsere Kunden haben den Mehrwert der besser ausgesuchten Materialien, der Verarbeitung bei einem Preisunterschied von 10 bis 15 Prozent bei gleicher Ausstattung zu den Mitbewerbern. Was man auch nicht unterschätzen darf: Jede Waffe wird speziell auf den Kunden zugeschnitten. Nach dem Kauf eines typischen Serien-AR15 werden häufig viele Komponenten ausgetauscht, was dann beim Verkauf der Originalteile einen Wertverlust darstellt. Zusätzlich haben wir so keinen Lagerbestand, was die Nachhaltigkeit erhöht und der Kunde bekommt so immer die neuste Fertigung.

SPARTANAT: Wie lange dauert die Fertigung in der Regel?

Schreiterer: Nachdem wir den Kunden neutral beraten haben und die Details geklärt sind, dauert es 5 bis 12 Wochen bis die Waffe fertig ist.

SPARTANAT: Sie sponsern auch IPSC Schützen? Wen genau?

Schreiterer: Wir zählen Dirk Frey, Sascha Back und Jochen Richter zu unseren Werksschützen. Sie wirken auch aktiv bei der Produktverbesserung mit, wie zum Beispiel bei unseren neuen Kompensatoren.

SPARTANAT: Gibt es Behördenaufträge?

Schreiterer: Aktuell nicht, da sich Beschaffer nicht intensiv mit dem Produkt auseinandersetzen möchten. Das wäre allerdings gerade durch das Customizing speziell für kleinere Einheiten interessant, die wir gern bedienen.

SPARTANAT: Eine letzte Frage: Was macht DAR besonders?

Anmerkung von SPARTANAT: Das Railsystem ist im Video noch einmal sehr gut erklärt (siehe Artikelanfang).

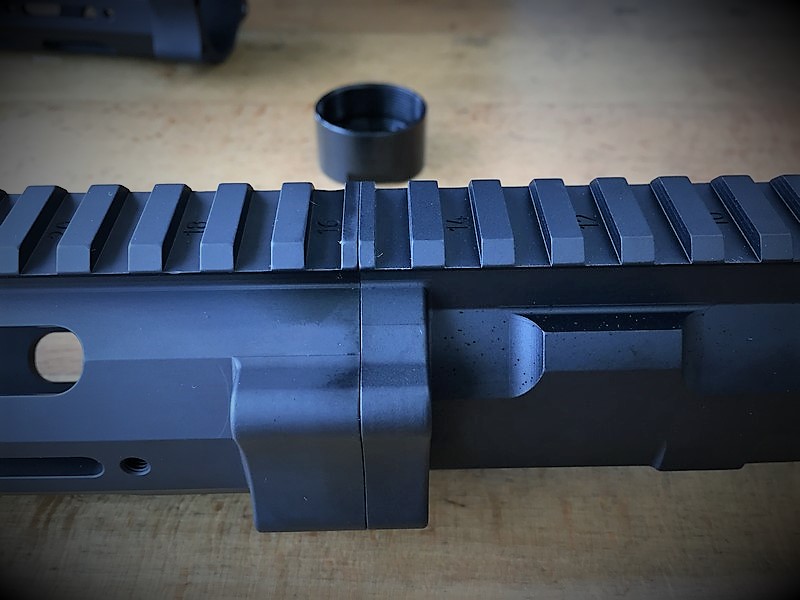

Schreiterer: Hier verweise ich immer gerne auf unsere Webseite, wo genau diese Frage beantwortet wird: https://www.dar-germany.com/das-besondere/. Wir sind europaweit das einzige Unternehmen, was FULL CUSTOM anbietet. Außerdem hat sonst niemand einen direkten Webshop, was gerade bei den freien Bauteilen interessant ist. Einzigartig ist auch das System unserer Vorderschäfte. Durch die Montage des Vorderschafts am Gehäuseoberteil und nicht an der Laufhaltemutter wie bei anderen Herstellern ergibt sich ein echter Freischwinger über den kompletten Lauf. Die Picatinny Schiene wird durch diese Befestigung quasi unterbrechungsfrei und lässt sich durchgehend mit allen Optiken nutzen.

SPARTANAT: Vielen Dank, Herr Schreiterer, wir sind gespannt was Sie uns nun zeigen und was die Gewehre auf dem Schießstand leisten.

Schreiterer: Sehr gerne. Wir haben auch alle bisherigen Produkttests zum Nachlesen auf unserer Seite hinterlegt, falls Ihr Euch noch eine andere Meinung einholen wollt: https://www.dar-germany.com/presse/.

DAR Kundenwaffe

Schalldämpfer

DAR Kundenwaffe

Schalldämpfer im Vorderschaft integriert

Nach dem Interview wurden wir durch die heiligen Hallen geführt. Da das Unternehmen recht klein ist, bekam man sehr schnell einen guten Überblick über die komplette Konstruktionskette: Nach dem Empfangsraum wurde uns der Tresorraum gezeigt. Hier lagern Munition, Zubehörteile von Magpul und Kundenwaffen, die zur Auslieferung bereitstehen.

Nach dem Interview wurden wir durch die heiligen Hallen geführt. Da das Unternehmen recht klein ist, bekam man sehr schnell einen guten Überblick über die komplette Konstruktionskette: Nach dem Empfangsraum wurde uns der Tresorraum gezeigt. Hier lagern Munition, Zubehörteile von Magpul und Kundenwaffen, die zur Auslieferung bereitstehen.

Gegenüber ist die Werkstatt mit Kleinteillager untergebracht. Dort werden die Waffen montiert. Interessant auch zu sehen, wie penibel DAR mit der Fertigung ist. Ein in unseren Augen einwandfreier Lower gehört zum Ausschuss, weil ein Teil nicht sauber glatt gefertigt wurde. Die nächsten Räume sind für den Versand und die Konstruktion gedacht. Zwei moderne PC-Arbeitsplätze bieten den Konstrukteuren alles, was sie für Ihre Arbeit brauchen. Für das Marketing ist ein kleines Fotoatelier vorhanden. Der letzte und größte Raum fasst die CNC-Fräse und auch die anderen Maschinen, die zur Fertigung benötigt werden.

Die nächsten Räume sind für den Versand und die Konstruktion gedacht. Zwei moderne PC-Arbeitsplätze bieten den Konstrukteuren alles, was sie für Ihre Arbeit brauchen. Für das Marketing ist ein kleines Fotoatelier vorhanden. Der letzte und größte Raum fasst die CNC-Fräse und auch die anderen Maschinen, die zur Fertigung benötigt werden.

Die große AR10 …

… und die kleine .223.

Nun, da wir alles gesehen haben, wollen wir nun endlich auf den Schießstand und die Gewehre ausprobieren. Die Wahl fiel auf eine IPSC DAR-AR15 mit Carbonvorderschaft, ein Präzisions-AR15 und eine AR10 im Kaliber .308. Die IPSC AR15 schoss sich unglaublich ausgewogen und leicht, was dem neuen Kompensator von DAR zu verdanken ist.

Die IPSC AR15 schoss sich unglaublich ausgewogen und leicht, was dem neuen Kompensator von DAR zu verdanken ist. Der Wirkungsgrad lässt die Waffe kaum nach oben schwingen: Schnelle Schlussfolgen sind problemlos möglich.

Der Wirkungsgrad lässt die Waffe kaum nach oben schwingen: Schnelle Schlussfolgen sind problemlos möglich. Auch in Sachen Präzision glänzten die beiden Gewehre im Kaliber .223 und .308 – mit normaler Fabrikmunition und ohne die Waffe gut zu kennen waren bereits nach ein bis zwei Schuss enge Schussbilder auf 100 Meter leicht machbar.

Auch in Sachen Präzision glänzten die beiden Gewehre im Kaliber .223 und .308 – mit normaler Fabrikmunition und ohne die Waffe gut zu kennen waren bereits nach ein bis zwei Schuss enge Schussbilder auf 100 Meter leicht machbar.

FAZIT: Wer ein Präzisions-AR15 sucht und die Waffe genauso gebaut haben will, wie sie in der Vorstellung existiert, sollte den Kontakt mit Dynamic Arms Research suchen. Hier lassen sich fast alle Wünsche verwirklichen – und das mit freundlicher und höchst kompetenter Beratung.

Vielen Dank an Dynamic Arms Research für den Einblick! Wenn Ihr gerne mehr über DAR wissen wollt, schaut immer mal wieder bei uns vorbei: Unser Interesse ist geweckt und wir werden auf jeden Fall die ein oder andere Waffe in einem separaten Review behandeln.

DYNAMIC ARMS RESEARCH im Internet: www.dar-germany.com

Zum Abschluss noch zwei professionelle Bilder der DAR Waffen von Sascha Back (http://www.saschaback.de/):

SPARTANAT ist das Online-Magazin für Military News, Tactical Life, Gear & Reviews.

Schickt uns eure News: [email protected]

Werbung

Hol Dir den wöchentlichen SPARTANAT-Newsletter.

Dein Bonus: das gratis E-Book von SPARTANAT.