Get the weekly SPARTANAT newsletter.

Your bonus: the free E-Book from SPARTANAT.

Mobile Smart Factory: Spare parts for military vehicles in the field

The Düsseldorf technology group Rheinmetall presented a new solution for mobile spare parts production for military vehicles to repair combat damage at an event of the European Defence Agency (EDA).

Rheinmetall Landsysteme GmbH, an OEM for tactical and logistical tracked and wheeled vehicles, presented the new concept for mission support. The new Mobile Smart Factory (MSF) is fully integrated into Rheinmetall's digital ecosystem IRIS (Integrated Rheinmetall Information System).

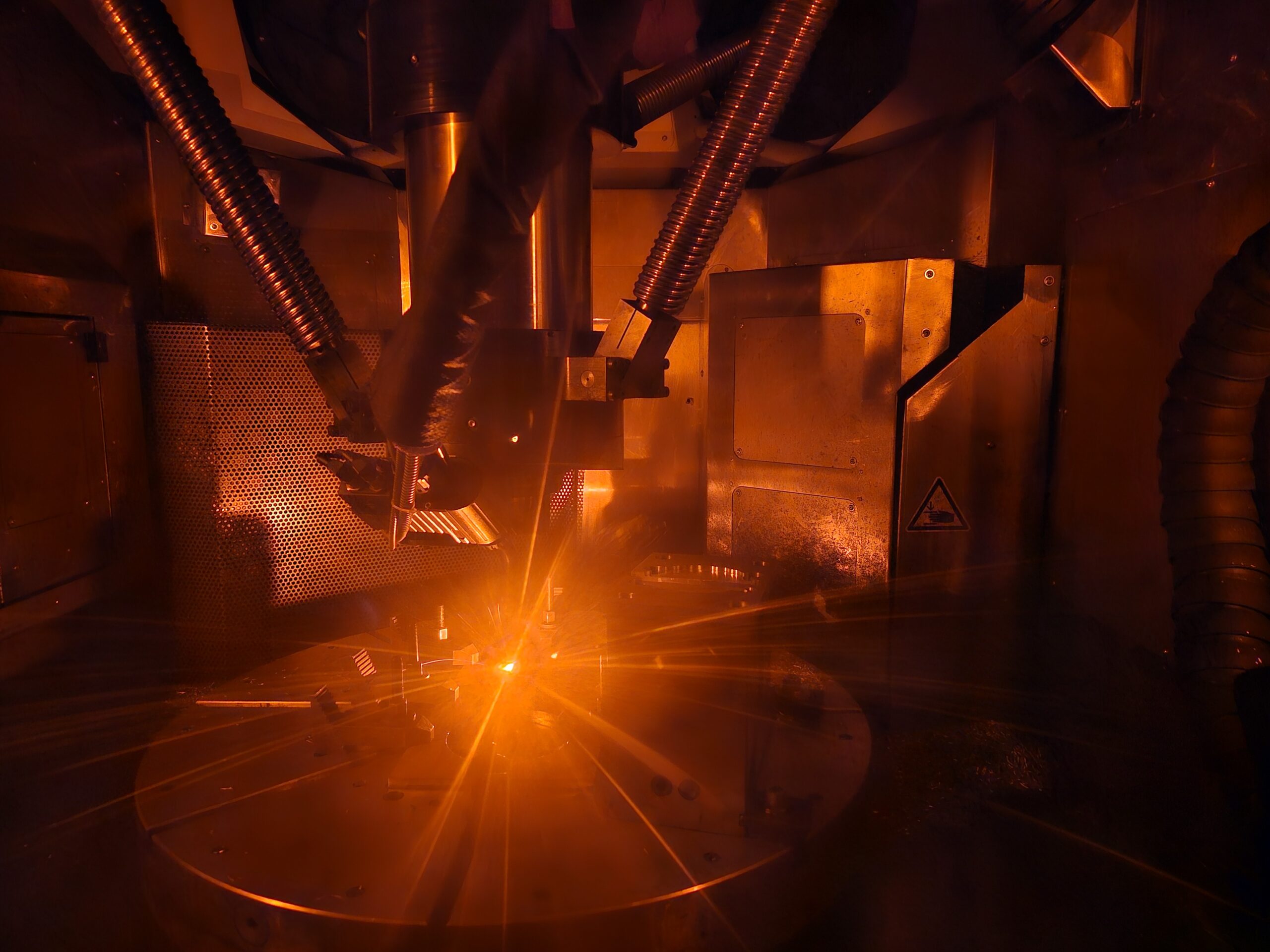

The MSF consists of two 20-foot mobile ship containers, one serving as an office container and the other as a production container. The office container houses an air-conditioned office with a workspace and storage space. It also includes an additional polymer printer and a handheld scanner. The production container is equipped with a Metrom P7000, a 6-axis hybrid machine. This machine is not limited to additive manufacturing with WAAM technology (Wire Arc Additive Manufacturing). Thanks to an integrated CNC milling facility, it also allows for on-site post-processing. The combined welding and CNC capabilities give field repair personnel additional options to address combat damage. Therefore, the MSF lives up to its name "Mobile Smart Factory."

The machine can produce components up to a maximum size of 700 mm in diameter and 450 mm in height. It can use all weldable wires and polymers. The deposition speed for metal is up to 600 cm3/h (cubic centimeters per hour).

What makes the Mobile Smart Factory unique is its integration into the IRIS platform. As an OEM of military vehicles, Rheinmetall understands the importance of secure data exchange and lifelong product monitoring of printed parts including relevant quality assurance. The cloud-enabled IRIS platform enables the fully integrated operation of software applications IRISwork and IRISfleet with the MSF, meeting IT security standards up to NATO-Restricted level. IRISwork provides operators and maintenance personnel access to technical documents and spare parts catalogs, while IRISfleet, as a fleet management tool, documents the installation of a specific printed part in a specific vehicle. IRISfleet stores all relevant information about the printed component and maintains a digital product passport to ensure system security. The IRIS technology also includes access to remote support by industry, engineers, quality assurance, etc. The collaborative IRIS platform allows the armed forces and the defense industry to engage partners in a secure network and provide quickly deployable additive capabilities for the modern battlefield.

RHEINMETALL on the Internet

SPARTANAT is the online magazine for Military News, Tactical Life, Gear & Reviews.

Send us your news: [email protected]

Ad

similar

Get the weekly SPARTANAT newsletter.

Your bonus: the free E-Book from SPARTANAT.